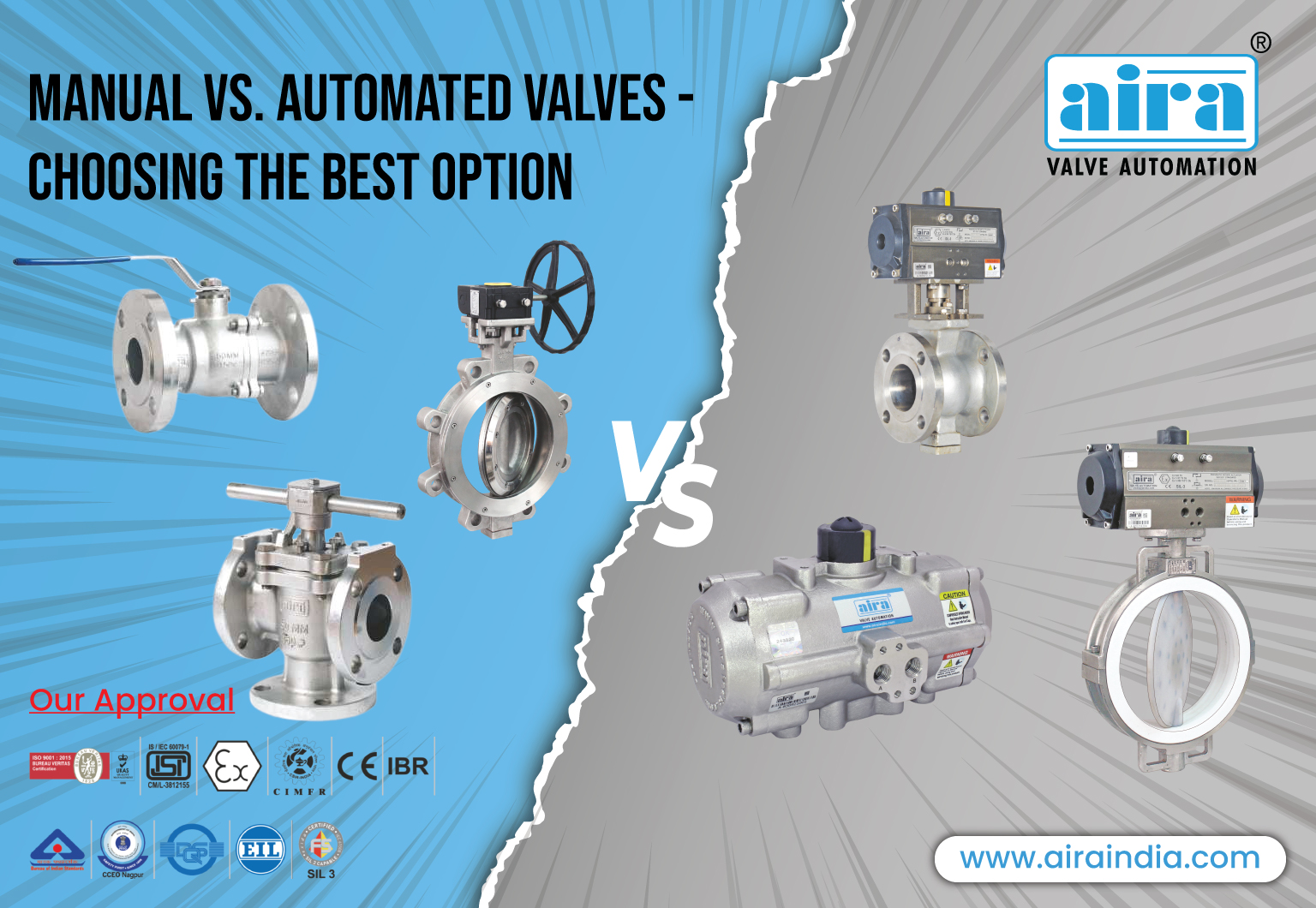

The cost difference between manual and automated butterfly valves is a significant factor in choosing the right valve for your application. Manual butterfly valves, which can be lever-operated or gear-operated, are generally more cost-effective upfront due to their simpler design and lower complexity. However, automated butterfly valves, which use pneumatic, electric, or hydraulic actuators, offer greater control and precision in regulating fluid flow, leading to increased efficiency and safety.

The initial cost of an automated butterfly valve may be higher than that of a manual valve, but the long-term benefits such as reduced labor costs, better process control, and minimal human intervention can offset the higher upfront investment. The cost of both manual and automated butterfly valves can vary depending on factors such as material, size, pressure rating, brand, and manufacturer.

Valves are essential components in many industrial processes, regulating the flow of fluids or gases within a system. They play a vital role in maintaining stable and efficient operations in industries such as oil and gas, water treatment, chemical processing, HVAC, and manufacturing. As a result, when comparing the cost of a 100mm manual and automated butterfly valve, it is critical to evaluate both the initial purchase price and the long-term operational expenses and return on investment depending on your individual application needs.

Manual Control Valves:

Definition of Control Valve

Manual control valves are mechanical devices used to regulate the flow of fluids or gases inside a system. These valves feature a handle or lever that must be manually manipulated to open or close the valve, hence controlling the flow of fluid or gas.

They are classified into several varieties, including gate valves, ball valves, and globe valves, and are employed in a variety of industries for specialized purposes.

Manual control valves are straightforward to use and operate, making them perfect for applications requiring constant flow rates. They are also suitable for low-pressure applications because of their strong structure, which can tolerate hostile conditions.

How they work

Manual control valves use a basic mechanism that requires twisting a handle or lever. The handle or lever rotates the valve stem, opening or closing the valve by moving a gate or ball. When the valve is open, fluid or gas passes through it and exits the system.

When the valve is closed, the flow is halted, thus the fluid or gas cannot escape. The degree of rotation of the handle or lever governs the flow rate via the valve, providing for fine flow control. Manual control valves are dependable and easy to maintain due to their simple mechanism.

Advantages of Manual Control Valves

Manual control valves have numerous benefits that make them useful in a variety of industrial applications. One notable benefit is their simplicity of design and ease of usage, making them more dependable than electronic valves.

They also provide a high level of accuracy because their operation relies on a person’s tactile senses, which allows for more precision. Furthermore, manual control valves are resilient and strong, making them perfect for usage in difficult environments where other types of valves may be ineffective.

They also cost less than electronic control valves and require less maintenance and repair. Finally, manual valves do not require external power sources to function, making them excellent for situations where power supplies are unreliable.

Disadvantage of Manual Valves:

Manual control valves have some drawbacks when compared to their electronic equivalents. One of the major disadvantages of manual control valves is their limited ability to regulate the flow of liquids or gases.

Operators must be physically present to regulate the flow of the valve, which can be difficult when attempting to maintain uniformity in a process. Furthermore, manual valves are not suitable for high-pressure systems or applications that demand frequent flow rate modifications. Human error is also a concern, since workers may forget to stop valves or not turn them far enough, resulting in system failure.

Electric Control Valves:

Definition of Electric Control Valves:

Electric control valves employ electrical impulses to control the flow of fluids or gases. They are sophisticated control systems that allow fluid or gas flow rates to be adjusted more quickly, precisely, and automatically.

Electronic control valves employ an electronic signal to regulate the position of the valve’s actuator, causing the valve to open and close. These valves are widely used in process control and automation applications requiring great precision and dependability.

They may be set to manage a precise flow rate and run on automated systems, which reduces the need for a human operator to physically manipulate the valves. Electronic control valves are utilized in many sectors, including oil and gas, water treatment, and manufacturing.

How they work:

Electric control valves use an actuator that is activated by an electrical signal to automatically alter the valve’s opening and shutting to regulate fluid or gas flow. The actuator receives electrical impulses from a controlling device or computer system, causing the valve to open or close to the required extent, allowing for precise flow control.

Electric control valves work on a variety of power sources, including DC, AC, and pneumatic. The valves are modular, allowing for quick component replacement and maintenance. Electric control valves are more complex than manual valves, which makes them more susceptible to system failures if electrical components fail.

Advantages of Electric Control Valves:

Electric control valves use an actuator that is activated by an electrical signal to automatically alter the valve’s opening and shutting to regulate fluid or gas flow. The actuator receives electrical impulses from a controlling device or computer system, causing the valve to open or close to the required extent, allowing for precise flow control.

Electric control valves work on a variety of power sources, including DC, AC, and pneumatic. The valves are modular, allowing for quick component replacement and maintenance. Electric control valves are more sophisticated than manual valves, making them more prone to system failures if electrical components malfunction.

Disadvantages:

There are certain downsides to electric control valves as compared to manual control valves. They are frequently more expensive than manual valves, and the initial installation and configuration can be time-consuming.

They also have more sophisticated designs, making them more prone to failure and needing specialized care and repair. Electronic control valves are also dependent on external power sources, which can be challenging to manage in areas with variable power or weak electrical infrastructure.

Finally, electronic control valves may need periodic calibration or tuning to assure peak performance, increasing the overall cost of maintenance.

Manual Control Valves vs. Electric Control Valves:

Comparison of Cost:

When comparing electronic versus manual control valves, pricing is an important issue to consider. Manual control valves are often less expensive to acquire, install, and maintain than electronic control valves. Manual valves are less sophisticated and frequently cheaper.

However, they require more upkeep and may lack accuracy. Electronic valves provide sophisticated features with excellent accuracy. They can be pricey, but they require less upkeep and are less prone to human mistakes. Finally, the decision between electronic and manual control valves is determined by the individual application and budget restrictions.

Comparison of Accuracy:

Automated control valves are substantially more accurate than manual control valves. Electronic valves employ modern control systems to ensure accurate opening and shutting.

Automated systems track and alter locations hundreds of times per second. This makes manual valves less exact since they rely on human perception. Electronic valves are suitable for precise applications.

Comparison of Versatility:

Automated control valves provide more adaptability than manual control valves. Electronic valves can manage a wide variety of flow rates and pressures. They can account for differences in system circumstances.

Manual valves require greater human interaction. Electronic control valves are compatible with automated systems, allowing for remote control and monitoring. This increases efficiency and reduces operating expenses.

Manual control valves are best suited for low-pressure systems or where precise flow control is not required. Manual valves are also ideal for scenarios in which there is no access to electricity or other power sources required to operate electronic control valves.

Finally, the decision between electronic and manual control valves is based on the unique application and its needs.

Comparison of Maintenance:

There is a significant difference between electronic and manual control valves regarding maintenance. Electronic control valves require less maintenance than manual ones since they have fewer moving components and are automated. However, Automated valves can be complex, requiring specialized training and expertise to diagnose and repair.

In contrast, manual valves are easy to maintain and repair, and maintenance can typically be performed by trained personnel. Servicing manual valves often requires less time, effort, and resources than with automated valves.

Manual valves may be frequently maintained in harsh environments with wear and tear. The choice between automated and manual control valves depends on the intended application and budget constraints.

Conclusion

Electronic and manual control valves differ in cost, accuracy, versatility, and maintenance. Electronic valves offer high accuracy and can handle various flow rates and pressures, reducing human intervention. They can integrate into automated systems, but are generally more expensive and require specialized maintenance.

Manual valves are less expensive but require more maintenance and are less precise. The choice between electronic and manual valves depends on the specific application and requirements, with factors such as cost, precision, reliability, and ease of maintenance being crucial. At Aira Euro Automation we are the leading Valve Manufacturer in India. We are well-known for manufacturing high-quality Ball Valves, Butterfly Valves, and Gate Valves for both Manually operated and Electrically Operated.