Approvals

The double acting pneumatic rotary actuators are available with 180° rotation. The quarter-turn family valves like ball valves, butterfly valves, and plug valves required only 90° rotation to come into action. While multi-way valves like 3 way or 4 way valves require 180° rotation, because of this the double acting pneumatic actuator 180° is used. To operate a multi-way ball valve or plug valve remotely, you need to install the pneumatic actuator with 180° rotation. There are 180° Pneumatic Single Acting Rotary Actuators Rotates are also available.

Specification & Standard

Size Range

ARA-328 To ARA-1108

Temperature Range

-20°C TO 90°C

Working Pressure

4 To 8 Bar

Method Of Transmission

Rack And Pinion Type

Actuation

Double Acting

Body

Extruded Aluminium Hard Anodized

Caps And Rack

Aluminium Pressure Die Cast

Pinion

EN 8

Seals

Nitrile

Air Pressure

Normal Air Supply Pressure: 3KG/CM², Air Supply Pressure: 8KG/CM² Max

Actuator Design

ISO 5211 (Actuator Can Be Quickly And Easily Mounting)

Rotation

180° Rotation

Torque

0 To 140 NM

Mounting PCD

As Per ISO 5211 Mounting Standard

Piston Material

Aluminium

Application

Operating For Valve

1 – Suitable typically for 3 way vales, requiring ON – OFF operation. It is available in both double acting versions.

2 – The 180° actuator can provide center off for the 3 way ball valve, bottom entry by choosing the option,of 3 position.

3 – The end stop adjustment is provided for opening and closing direction as a standard.

4 – Actuator mounting is as per ISO 5211 & Accessories to Namur Solenoid Valve.

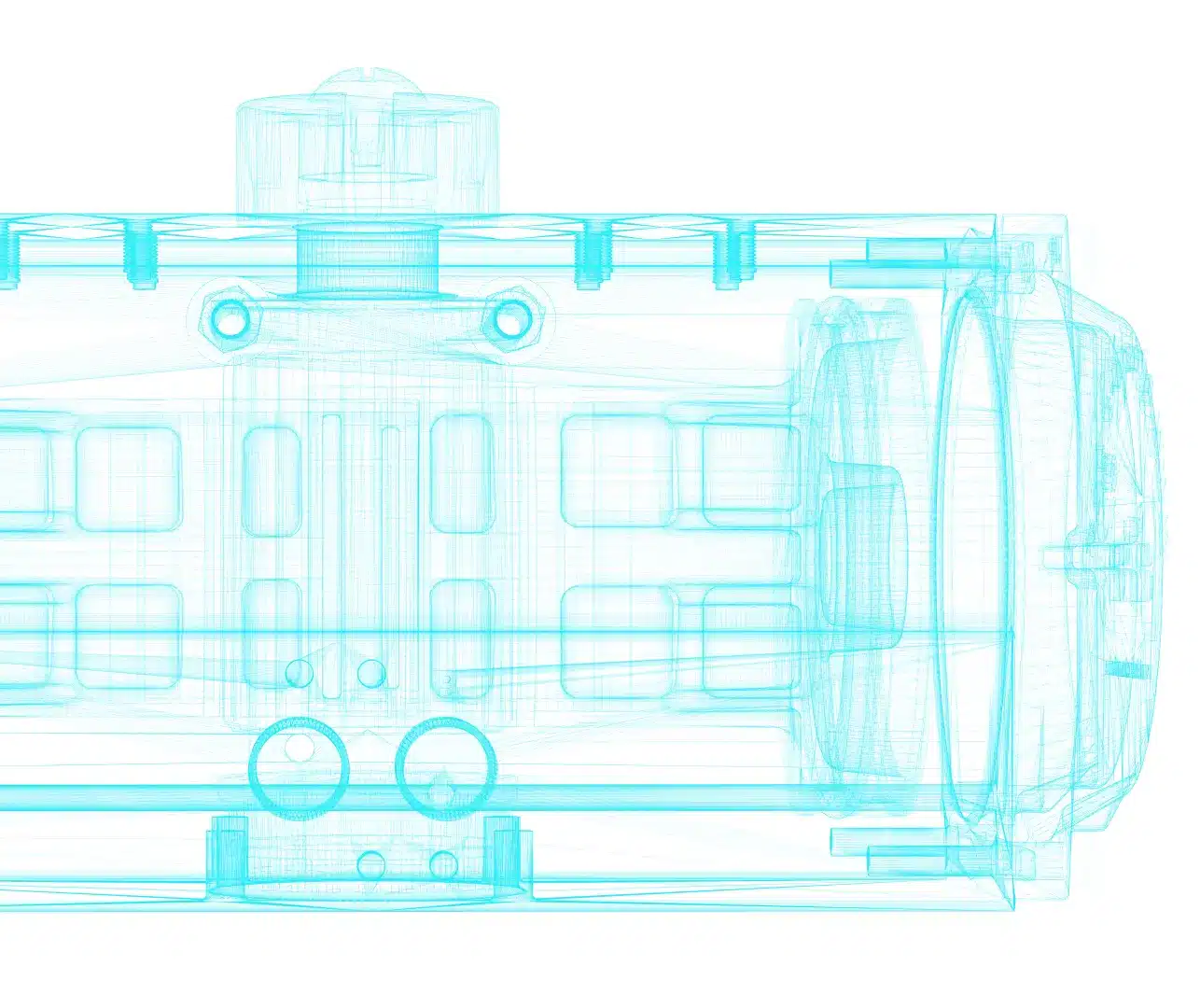

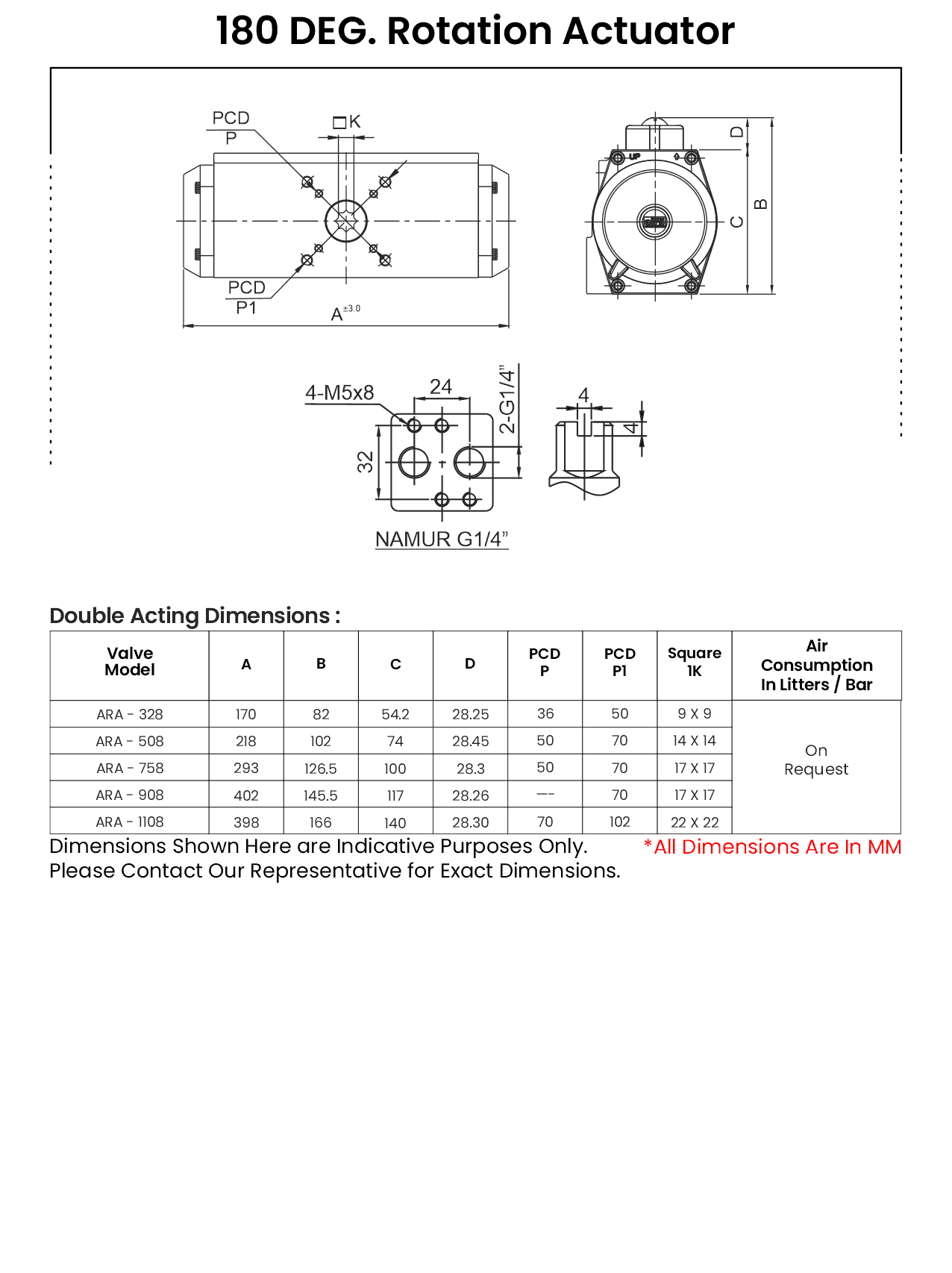

180° Rotation

Double Acting Actuator

180° Rotation

Double Acting Actuator

Dimension Table

Related Products

Working Days: Monday to Saturday.Tell Us How We Can Help You

Request A Quote

Complete control over products allows us to ensure our customers receive the best quality prices and service