Approvals

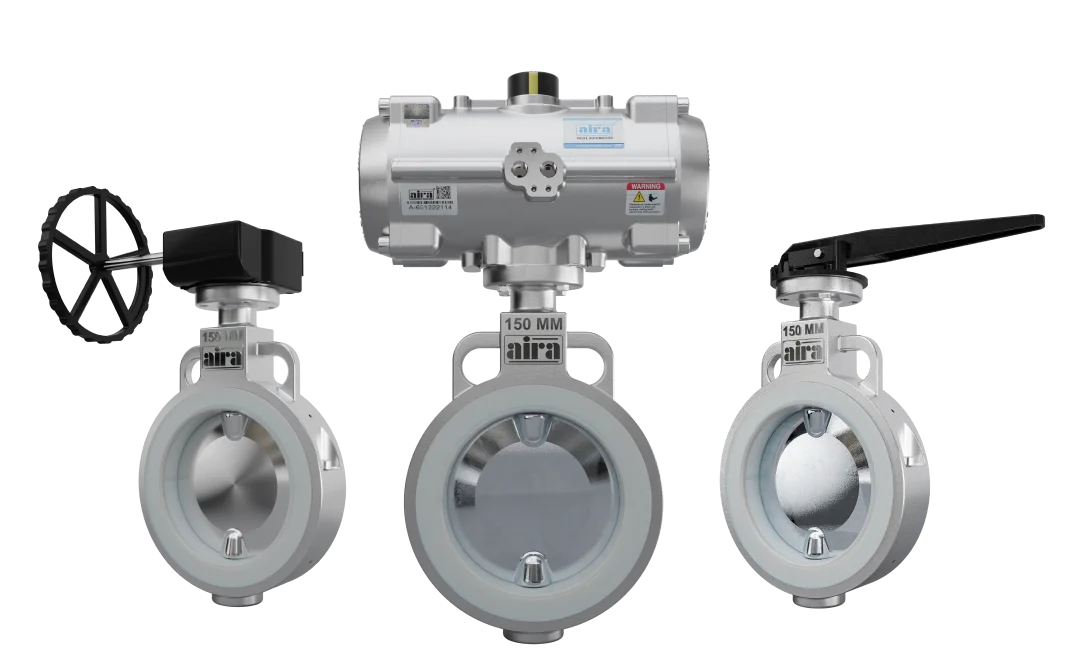

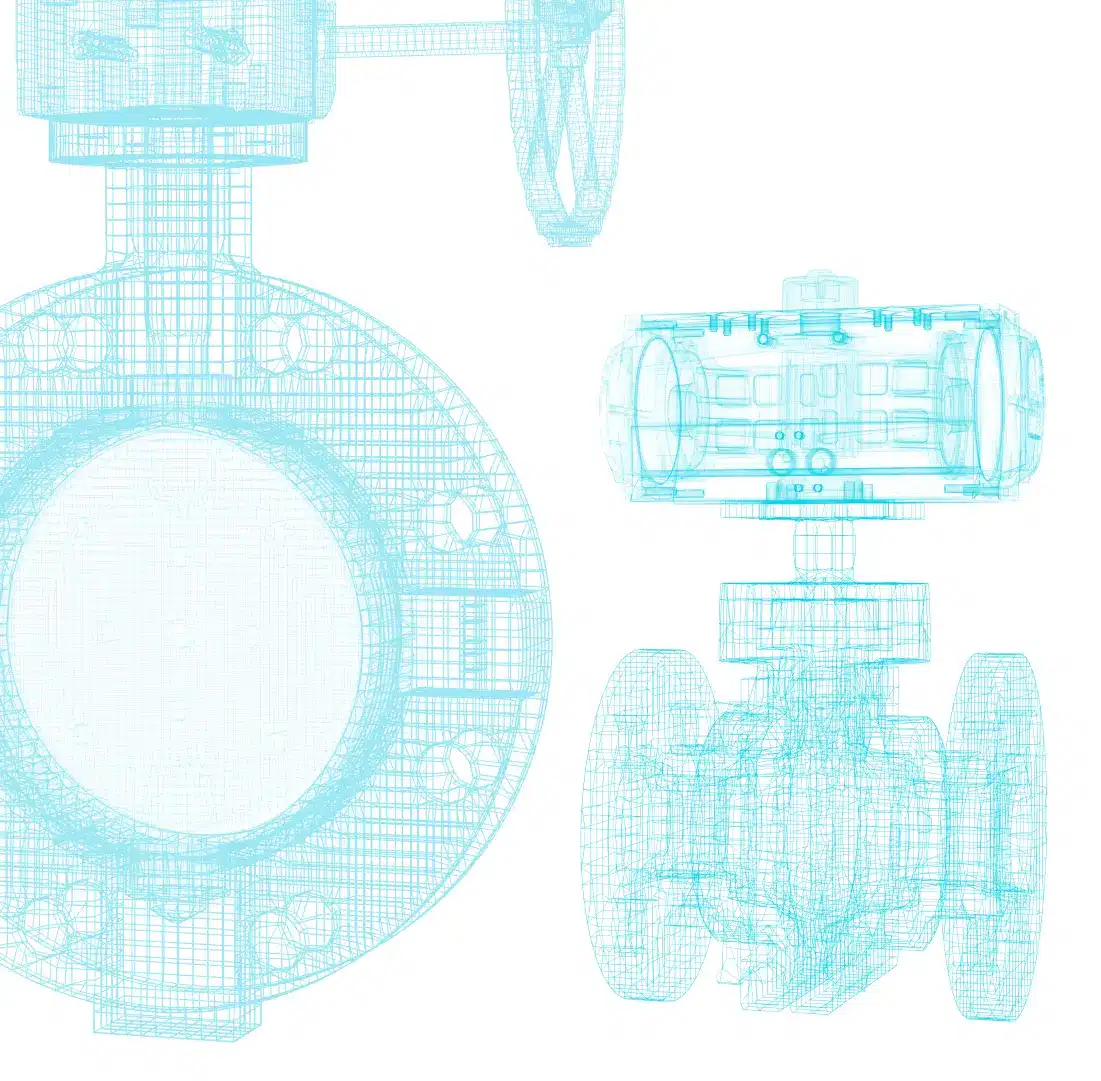

Aira Euro Automation Offer Pneumatic Actuator Operated Techo Model S.G. Iron / CF8 / CF8M Body & CF8 / CF8M Disc 2 Piece Body Teflon Sleeve Butterfly Valve with Mirror Finish Disc PN 10 (Replaceable Muffler)

Specification & Standard

Design & Manufacturer

API 609 Category A/ BS- EN- 593

Valve Face To Face Dimension

API 609 Category A

Inspection & Testing

API 598/ BS EN 12266 PART - 1

Leakage Class

Class Vi

End Connection

Wafer Type

Valve Rating

Flanged 150#

Spark Test

15 KV DC to 40 KV DC

Body Type

Wafer Type

Stem Material

CF8, CF8M, WCB + ENP, HAST ALLOY, DUPLEX, MONEL, CF3M

Size Range

2'' to 24'' (50MM To 600MM)

Temptreature Range

-50' C To 300' For Soft Seated Valves. Contact Works For Special Requirement

Pressure Class

PN-6

Body Material

CAST IRON(CI), DUCTILE IRON(DI), S.G IRON(SGI), WCB, CF8, CF8M, CF3M, SS 304L, DUPLEX, HAST ALLOY, MONEL

Disc Material

CF8, CF8M, WCB + ENP, HAST ALLOY, DUPLEX, MONEL, CF3M

Sleeve Material

PTFE, RPTFE, CFT, GFT, TFM-1600, AIRA-250, NYLON, DEVLON, PEEK

Flanged Drilling

ISO 5211 II

Fugitive Emissions

Yes

Shout Off Rating

Vi Class

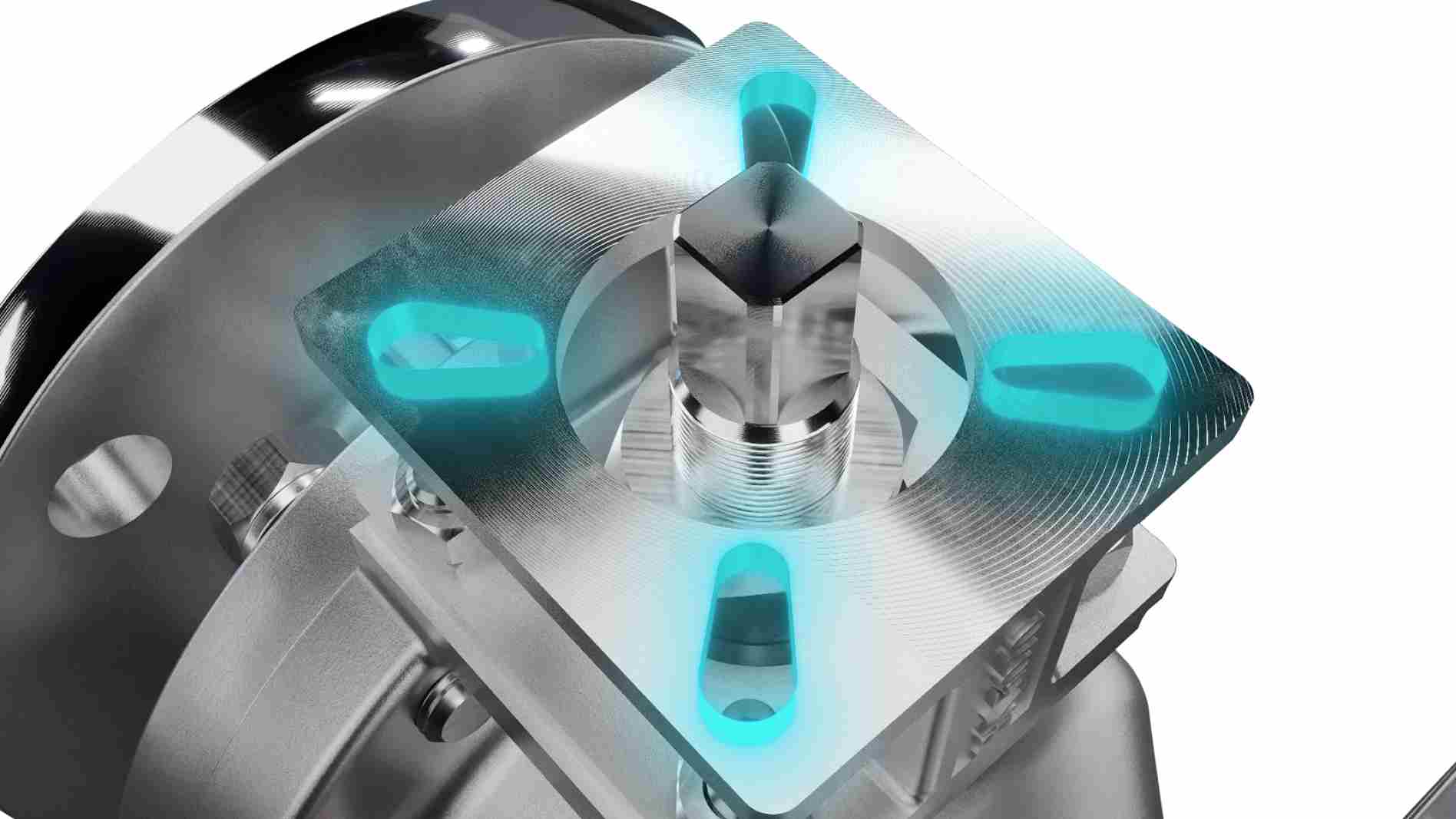

1 – UPPER STEM BUSHING: An upper stem bushing, retainer by a stainless steel ring, is provide to absorb actuator side thrusts and is acetal as standard or PTFE as an option.

2 – UPPPER STEM SEAL: Keeps environmental contaminants from entering the stem bore.

3 – BODY: Bodies are two piece wafer or lug style and are epoxy coated.All bodies meet full ASME Class150 or DIN 3840 flange drilling requirements (24” body is double flanged).

4 – BEARINGS: PTFE impregnated steel bearing provided for the precision alignment of the upper and lower stem.

5 – BLOWOUT PROOF STEM: A shoulder is machined into the upper stem. The stem and the disc are pressed together during assembly creating a positive stem to disc connection.

6 – PRIMARY SEAL: The primary seal is achieved by an interference fit between the extra wide disc hubs and contoured seat.

7 – SEAT DESIGN: The unique seat geometry lowers seating unseating toque while reducing wear on the contacting parts.

PTFE Muffler

Mirror Finished Wafer Type Lined Butterfly Valve

PTFE Muffler

Mirror Finished Wafer Type Lined Butterfly Valve

Dimension Table

ADDONS

Related Products

Working Days: Monday to Saturday.Tell Us How We Can Help You

Request A Quote

Complete control over products allows us to ensure our customers receive the best quality prices and service