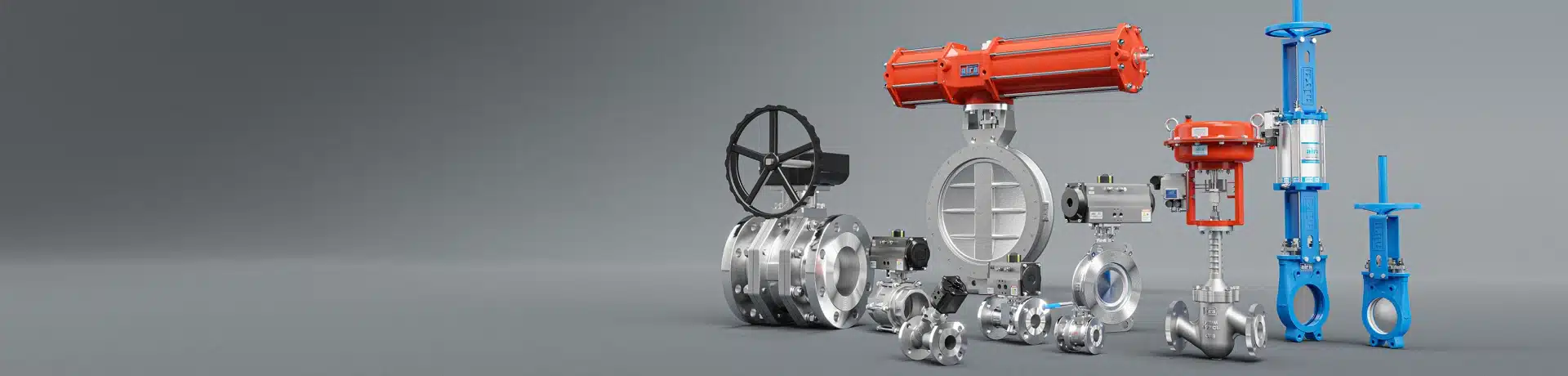

We provide a wide range of butterfly valves including pneumatic butterfly valves gear-operated, handle-operated, and wheel-operated, all designed for smooth flow control and long-lasting performance. Whether you’re looking for manual or automated options, Aira has the perfect solution for your industrial needs. As a leading pneumatic butterfly valve manufacturer, we focus on quality, reliability, and customer satisfaction. Choose Aira for valves that perform under pressure and deliver consistent results across various applications.

Types of Butterfly Valves We Manufactured.

Aira offers a complete range of butterfly valves designed to meet different industrial flow control requirements.

- Concentric Design Butterfly Valve

This standard valve features a centered disc and stem. It’s perfect for low-pressure and low-temperature applications, offering cost-effective sealing with elastomer-lined seats.

- Single Eccentric Butterfly Valve

Designed with a slightly offset stem, this type reduces disc-seat friction during operation, enhancing valve life and making it suitable for moderate-pressure applications.

- Double Eccentric Butterfly Valve

With two offsets in stem placement, it ensures minimal wear and quick sealing action. Ideal for handling liquids and gases under medium to high pressure.

- Triple Eccentric Butterfly Valve

Built for high-performance applications, this valve uses a conical sealing system to handle extreme pressure, temperature, and corrosive media with zero leakage.

- High Performance Butterfly Valve

Engineered for demanding industrial processes, it ensures long-lasting operation, low torque, and excellent sealing — ideal for oil & gas, power, and water systems.

- Damper Butterfly Valve

Designed for low-pressure systems involving air, gas, or dust, this valve controls airflow in ventilation and exhaust systems with reliable performance.

With a 100% in-house manufacturing facility and our own casting foundry, we guarantee faster delivery and consistent quality. As a leading pneumatic butterfly valve manufacturer, Aira also supplies valves with advanced pneumatic actuators backed by a 4-year warranty—a promise of performance and peace of mind.

Aira Butterfly Valve End Connections

Aira Euro Automation manufactures butterfly valves in a wide variety of end connection types to suit diverse piping systems and industry needs. Here’s a quick look at each type:

- Wafer Type

This is the most common and compact design. It fits snugly between flanges using bolts, making it ideal for space-saving installations and quick maintenance.

- Double Flange Type

This heavy-duty design comes with flanges on both ends for direct bolting to pipeline flanges. It offers superior strength and is preferred in high-pressure applications.

- Lug Type

With threaded lugs outside the valve body, this type allows easy installation or removal from one side of the pipeline without disturbing the entire system.

- Single Flange Type

Also known as semi-lug type, it’s used in dead-end service and lighter applications where only one side needs secure flange connection.

- But-welded Type

Designed for permanent installations, this type is welded directly into the pipeline. It ensures zero leakage and is suitable for high-temperature and high-pressure lines.

Aira Butterfly Valve Operating Systems

Aira Euro Automation offers butterfly valves with a wide range of operation modes to meet the demands of various industries. Whether your application requires automation or manual control, Aira ensures reliable performance, smooth operation, and durability with each actuation method. From pneumatic to electric and manual options, each system is engineered for precision flow control in diverse environments.

- Rack & Pinion Actuator

This pneumatic actuator uses linear air pressure to rotate the valve via a gear system. It’s compact, efficient, and ideal for fast, reliable automated operation.

- Scotch & Yoke Actuator

Used in heavy-duty applications, this actuator delivers high torque output and is best suited for larger valves and higher-pressure systems.

- Scotch & Yoke with Hydraulic MO (Manual Override)

Combining pneumatic actuation with hydraulic manual override, this system allows operators to manually control the valve during power or pressure failure.

- Worm Gear Box Manual

This gearbox-driven manual operation offers precise control with minimal effort, commonly used in large valves where hand levers aren’t practical.

- Hand Lever Manual

A simple and cost-effective manual option for quick open/close action, ideal for smaller valve sizes and general-purpose applications.

- Electric Actuator

Electric motor-operated valves allow remote and automated control, suitable for plants with electrical systems where pneumatic supply is not available.

Aira’s Butterfly Valve Pressure Class Options

At Aira Euro Automation, we manufacture butterfly valves in a wide range of pressure classes to suit various industrial applications — from low-pressure systems to high-pressure operations. With our 100% in-house facility and foundry support, we ensure precision and quick delivery across all pressure ratings.

- 150# – Standard ANSI class for general-purpose industrial applications handling moderate pressure.

- 300# – Suitable for higher-pressure environments requiring stronger sealing and structural strength.

- 600# – Designed for demanding high-pressure pipelines in oil & gas, power, and process industries.

- PN 2.5 – Ideal for very low-pressure operations like ventilation and low-pressure fluid systems.

- PN 6 – Common in light-duty applications such as water and HVAC systems.

- PN 10 – Preferred for low to medium pressure industrial systems including chemical and food plants.

- PN 16 – A widely used pressure class for waterworks, process plants, and general industries.

- PN 20 – Engineered for slightly higher pressure systems in utility and fluid control setups.

- PN 25 – Suitable for more robust operations involving water, steam, and industrial gases.

- PN 40 – Ideal for high-pressure systems in thermal, petrochemical, and offshore sectors.

- PN 50 – Built for critical applications with extreme pressure handling needs.

Aira Manufacturing Standard of Pneumatic Butterfly Valves

Aira Euro Automation adheres to globally recognized standards to ensure the highest quality and performance of our butterfly valves. Our commitment to excellence is reflected in the following manufacturing standards:

- API 609 – Category A: Applicable to our concentric Eco Tech series, designed for resilient-seated valves in low-pressure applications.

- API 609 – Category B: Pertains to our double and triple eccentric valves, available in short, medium, and long pattern designs for high-performance applications.

- BS EN 593 – BFV: Our valves comply with this European standard, ensuring reliable performance in industrial and water treatment applications.

- IS 13095 – BFV: Manufactured in accordance with Indian standards, our valves meet the specific requirements of domestic industrial operations.

- AWWA C504 – BFV: Our valves are designed to meet this American standard, suitable for waterworks systems requiring robust and reliable performance.

- AWWA C516 – BFV: We offer large-diameter valves conforming to this standard, ideal for high-pressure water distribution systems.

Aira’s Butterfly Valve Face To Face Standard

Aira Euro Automation designs its pneumatic butterfly valves to comply with a range of international face-to-face standards, ensuring seamless integration into diverse piping systems. Our adherence to these standards guarantees compatibility, reliability, and ease of maintenance across various industrial applications.

- API 609 – Category A: Our concentric Eco Tech series valves are manufactured to API 609 Category A specifications, ensuring standardized face-to-face dimensions for resilient-seated designs.

- API 609 – Category B: Our double and triple eccentric butterfly valves conform to API 609 Category B, offering short, medium, and long pattern options to meet specific application requirements.

- BS EN 558: Aira’s butterfly valves adhere to BS EN 558 standards, providing consistent face-to-face dimensions for flanged valves, facilitating straightforward installation and replacement.

- ASME B16.10: Our valves are designed in accordance with ASME B16.10, ensuring uniform face-to-face dimensions for a variety of valve types, promoting interchangeability and system compatibility.

- IS 13095 – Short and Long Pattern: Aira manufactures butterfly valves following IS 13095 standards, offering both short and long pattern face-to-face dimensions to suit different installation needs within Indian industrial contexts.

- AWWA C504 – Short and Long Pattern: Our valves meet AWWA C504 specifications, providing standardized face-to-face dimensions in both short and long patterns for waterworks applications.

- AWWA C516: Aira’s large-diameter butterfly valves comply with AWWA C516 standards, ensuring appropriate face-to-face dimensions for high-pressure water distribution systems.

Testing Standards of Aira Butterfly Valves

Aira’s Butterfly Valve Testing Standards

Aira Euro Automation ensures the highest quality and reliability of its butterfly valves through rigorous in-house testing facilities, accommodating sizes from small to large. Our adherence to internationally recognized testing standards guarantees that each valve meets stringent performance criteria.

- API 598: Aira conducts comprehensive testing, including shell and seat leakage tests, in accordance with API 598 standards to ensure valve integrity and performance.

- BS EN 12266-1: Our valves are tested for pressure and leakage as per BS EN 12266-1, ensuring compliance with European quality benchmarks.

- IS 13095: Aira’s testing procedures align with IS 13095, meeting Indian standards for butterfly valve performance and safety.

- AWWA C504: We perform tests in line with AWWA C504 to validate the suitability of our valves for waterworks applications.

- AWWA C516: For large-diameter valves, Aira adheres to AWWA C516 testing standards to ensure reliability in high-pressure water distribution systems.

Aira Butterfly Valve Shaft Options

Aira Euro Automation offers two distinct shaft configurations in its butterfly valves, catering to varied operational requirements and ensuring optimal performance across applications.

- Single Shaft (One Piece)

Aira’s one-piece shaft design provides robust structural integrity, ideal for applications demanding high torque and minimal maintenance.

- Split Shaft (Two Piece)

The two-piece split shaft configuration allows for easier assembly and disassembly, facilitating maintenance in systems where space constraints or operational considerations are paramount.

There Are 3 Options Available In the Top Shaft Design

Aira Euro Automation offers three distinct top shaft designs in its butterfly valves, catering to diverse operational requirements and ensuring optimal compatibility with various actuation mechanisms.

- Key-Way

Aira’s Key-Way shaft design provides a secure mechanical connection, ensuring precise torque transmission between the actuator and valve.

- Square

The Square shaft design by Aira facilitates straightforward actuator mounting, promoting ease of installation and reliable performance.

- Double “D” Type

Aira’s Double “D” shaft configuration offers enhanced alignment and stability, delivering consistent operation in demanding applications.

Butterfly Valve Seating Constructions

Aira Euro Automation offers a diverse range of seating materials for its butterfly valves, each engineered to meet specific operational requirements and temperature ranges.

- PTFE (-20°C to 180°C)

Aira’s PTFE seats provide excellent chemical resistance and low friction, ensuring smooth operation in various industrial applications.

- RPTFE (-45°C to 230°C)

The reinforced PTFE seats by Aira offer enhanced strength and higher temperature tolerance, suitable for demanding environments.

- GFT / CFT (-100°C to 220°C)

Aira’s GFT and CFT seats combine glass or carbon fillers with PTFE, delivering improved wear resistance and dimensional stability.

- PEEK (-56°C to 260°C)

PEEK seats from Aira are designed for high-temperature and high-pressure applications, offering exceptional mechanical strength.

- TFM 1600 (-200°C to 260°C)

Aira’s TFM 1600 seats provide superior chemical resistance and lower permeability, ideal for critical sealing applications.

- NBR (-23°C to 82°C)

Aira’s NBR seats are suitable for general-purpose applications, offering good resistance to oils and hydrocarbons.

- EPDM (-40°C to 120°C)

EPDM seats by Aira are ideal for water and steam applications, providing excellent resistance to heat and weathering.

- Viton (-20°C to 180°C)

Aira’s Viton seats offer superior chemical resistance, particularly against aggressive fluids and high temperatures.

- Neoprene (-35°C to 110°C)

Neoprene seats from Aira provide good abrasion and weather resistance, suitable for various industrial applications.

- Hyplon (-30°C to 130°C)

Aira’s Hyplon seats offer excellent resistance to chemicals and UV exposure, ideal for outdoor and harsh environments.

- Graphite (-196°C to 550°C)

Graphite seats by Aira are designed for extreme temperatures, ensuring reliable sealing in high-temperature applications.

Butterfly Valve’s Applications & Industries

Aira Euro Automation’s butterfly valves are engineered to meet the diverse needs of various industries, ensuring reliable performance across a wide range of applications.

- Vegetable Oils (Food Processing)

Aira’s valves ensure hygienic flow control in edible oil refining processes.

- Wastewater (Sewage Treatment)

Designed for efficient handling of wastewater in sewage treatment plants.

- Sludge (Waste Treatment Plant)

Robust construction allows for reliable management of sludge in waste treatment facilities.

- Fertilizers (Agriculture Systems)

Suitable for controlling the flow of various fertilizers in agricultural applications.

- Paper Pulp (Pulp and Paper Mills)

Ensures smooth operation in the handling of paper pulp during manufacturing.

- Latex (Rubber Manufacturing)

Provides precise flow control in latex processing within rubber production.

- Carbon Dioxide (Beverage Carbonation)

Maintains accurate CO₂ flow for beverage carbonation processes.

- Deionized Water (Electronics Manufacturing)

Ensures contamination-free flow of deionized water in electronics production.

and many more, including Hydraulic Oil (Hydraulic Systems), Treated Effluents (Environmental Treatment), Molasses (Sugar Processing), Biodiesel (Renewable Energy Systems), ASH Handling Water (Power Plants), Ethylene Glycol (Anti-Freeze Systems), Bitumen (Asphalt Production), Cryogenic Liquids (LNG storage systems), Ethylene (Petrochemical Process), Chlorine Gas (Water Treatment), Sulfuric Acid (Chemical Manufacturing), Milk (Dairy Processing), Juices (Beverage industry), Beer (Brewing Industry), Wine (Wineries), Solvents (Paint and coating industry), Resins (Adhesive production), Cooling Water (Industrial Cooling systems), Hot Water (Heating Systems), Firefighting Water (Fire Protection Systems), Condensate (Steam Systems), Oil-Based paints (Coating Industry), Petro Chemicals (refinary operators), Lubricating Oils (Industrial Machinery), etc.