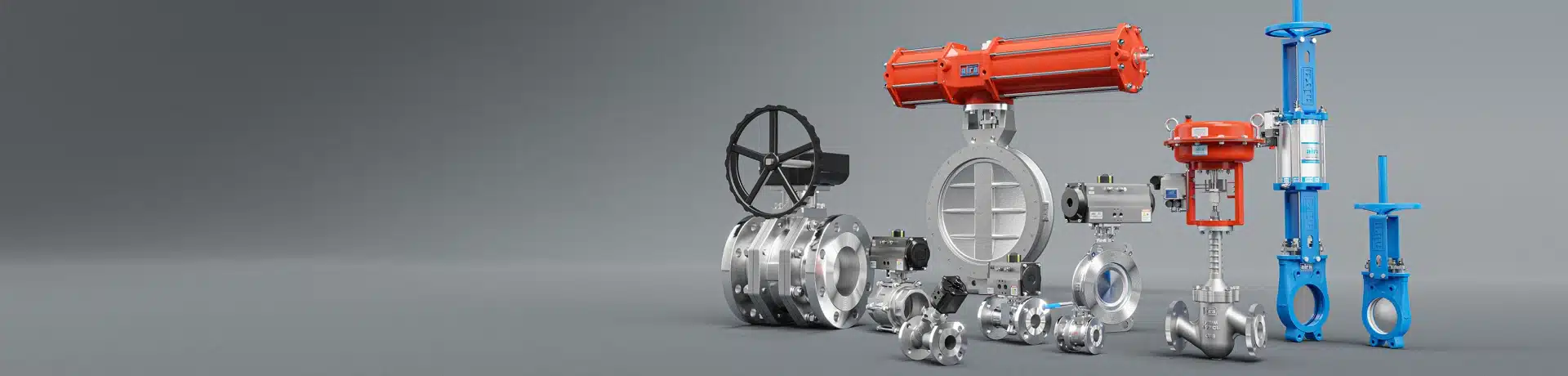

It exports Solenoid valves in more than 20 countries across the world including the Indian Ocean countries and the Gulf countries. This company has achieved an ATEX and a CE certificate for Solenoid Coils and has been approved for CCEO solenoid coils, flameproof coils and IS 3000 coils.

We, at Aira Euro Automation, use high graded quality materials and advanced technologies in building our products. We make sure to follow the ISO guidelines which lead us to be one of the well established leading brands in the valve industry.

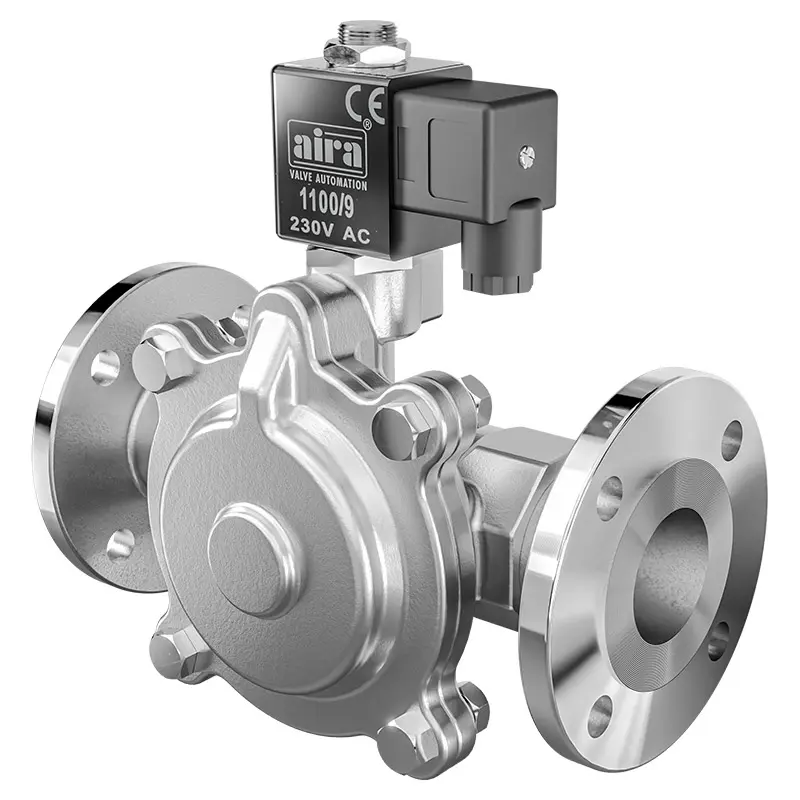

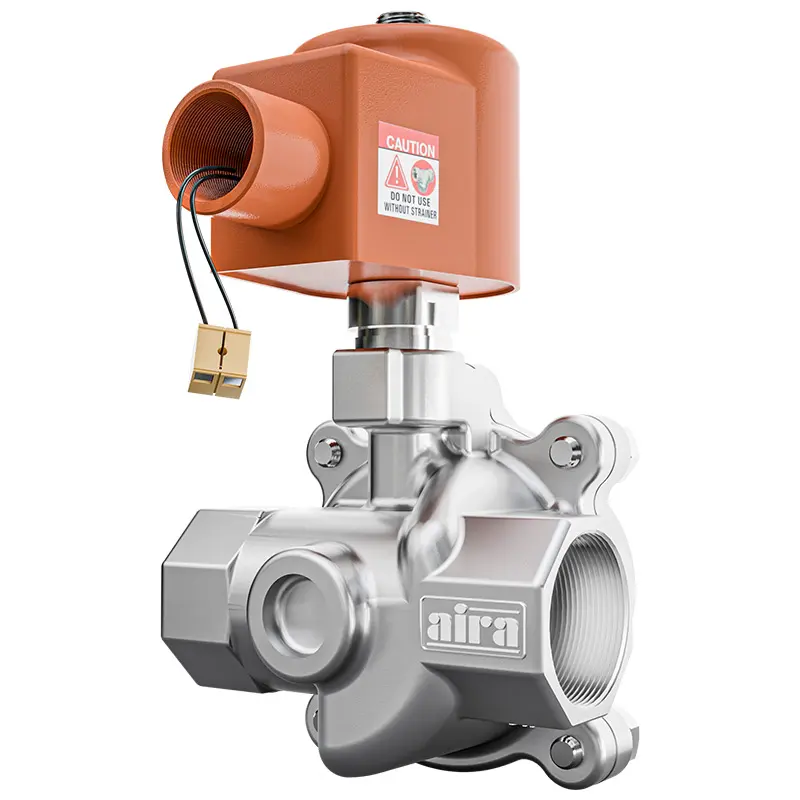

We provide a wide range of Solenoid Valves used in different applications and media, some of which are the Pilot operated, the Semi lift diaphragm, the Piston operated, the Union type, and others. There are mainly two types of solenoid valves that are most useful because of their power saving function: A normally open solenoid valve and a normally closed solenoid valve. The normally open valve is energized to stop the fluid and the normally closed valve is energized to open the fluid. We offer various customization options to our customers as per their requirements and demands.

We boast of having maintained a high product quality because of our total inhouse production facility and our well set quality inspection department. We have a team of highly experienced engineers to make sure of serving a good quality end product. Each product goes through the inspection department to rectify any faults or errors if detected in our products. Only after thorough checking of the quality and the working of the product, it is delivered to our valuable customers.

Our valves are best known for their long durability, low cost maintenance, light-weight, and compact design.

These valves are used to control high & normal pressure Air, Water, Hot water, Steam, Chemicals, Oil, Gas, Vacuum and other high temperature fluids. They have a safe performance in hazardous environments and they control inflammable media as we provide flameproof and explosion proof coils with these solenoid valves.

We offer a huge range of solenoid valves with various features. From ½” inch to 6” inch sized valves are available with -5°C to 180°C working temperature capacity and 0.5 BAR to 110 BAR pressure sustaining capability. We provide all standards from 12V to 230V AC and DC flameproof coils. These solenoid valves come up with Screwed, Flanged, and Tri-Clover End Connections.

Our solenoid valves are available with various body materials to handle high temperature media. We provide various solenoid valves for various applications like Air, Water, Gas, Light Oil, Light Chemical, Vacuum, Corrosive Fluids, Autoclaves, Gas Burning Equipements, Pump Seal Water Application, High Volume and Low pressure Application, Hot water, Steam, Dust collector Application, Low Pressure Water Circulation System, Solar Heating System, Gas Generator, High Temperature Fluids, LD Oil, Chemical, Ceramic Filters, Drain and Dispensing, Oil Centrifuge Plants, low oil pressure, etc.

Our huge range of solenoid valves is upgraded with the latest technology and user friendly for new generations. Therefore our customers are very satisfied with our products.

We served many leading companies like Indian Oil, Reliance Industries Limited, ONGC, Hindalco, Godrej, GAIL, IFFCO, BARC, BHEL, etc. We also export to more than 30 countries around the world with the faith of quality and reliability.

Solenoid valves are a critical part of fluid and gas control systems in industries across the globe. Whether you’re managing water, air, oil, or steam, solenoid valves make automatic flow control possible.

Below are frequently asked questions (FAQs) that explain what they are, how they work, and the types available.

A solenoid valve is an electromechanical valve used to control the flow of fluids or gases. It works using an electric coil (solenoid) that opens or closes a valve seat when energized or de-energized. These valves automate fluid flow without manual effort.

Solenoid valves can be classified in two main ways: 1. Based on Port Configuration: – 2-Way Solenoid Valve – One inlet and one outlet. Used for simple on/off flow. – 3-Way Solenoid Valve – One inlet and two outlets (or vice versa). Used to mix or divert flow. – 4-Way / 5-Way Valves – Common in pneumatic systems, used to control double-acting cylinders. 2. Based on Mode of Operation: – Direct-Acting Solenoid Valve – Indirect (Pilot-Operated) Solenoid Valve – Semi-Direct Acting Solenoid Valve

When electric current passes through the solenoid coil, it generates a magnetic field. This field pulls a plunger or armature inside the valve body, either opening or closing the flow path. – If the valve is Normally Closed (NC): it stays shut until powered. – If the valve is Normally Open (NO): it stays open until powered.

In a direct-acting solenoid valve, the solenoid directly pulls the plunger to open or close the valve. There’s no need for system pressure to assist in the operation.

Key features:

An indirect-acting or pilot-operated solenoid valve uses system pressure to open or close the main valve. The solenoid only controls a small pilot hole that allows pressure movement. Key features: – Suitable for high flow and high pressure – Requires minimum pressure differential (usually 0.5 bar or more) – Common in water supply, HVAC, and industrial systems

A semi-direct acting valve combines both direct and pilot operation. The plunger also opens a pilot hole and assists the diaphragm or membrane in lifting. Key features: – Operates at low or zero pressure – Handles higher flow than direct-acting – Great for universal use across pressure ranges