When it comes to automation and fluid control, not all solenoid valve operate in the same way. Many engineers often feel confused when deciding between a direct acting solenoid valve and a pilot operated solenoid valve. Choosing the wrong type can lead to system inefficiency, unwanted downtime, or even failure. In this blog, we’ll clear up the confusion with a simple, side‑by‑side comparison so you can confidently select the right valve for your application.

What Is a Direct Acting Solenoid Valve?

A Direct Acting Solenoid Valve is designed so that the coil directly lifts or moves the plunger to open and close the valve. Unlike pilot operated models, it does not rely on system pressure or a pressure differential to function. This makes it ideal for low‑pressure systems, gravity‑fed flows, or applications with very small flow rates. These valves are commonly used in gas lines, chemical dosing systems, and various low‑pressure automation setups. Because they respond quickly and work without minimum pressure, they’re perfect when precise control is required.

What Is a Pilot Operated Solenoid Valve?

A Pilot Operated Solenoid Valve uses the system’s line pressure to assist in the actuation process. The solenoid only controls a small pilot orifice, and the main seal is opened using the fluid’s pressure. However, these valves require a minimum pressure differential of generally 0.5 bar or higher to operate properly. Pilot operated designs are preferred in high‑flow systems, large pipelines, and continuous operations. They are widely used in water treatment plants, compressed air systems, steam lines, and industrial processes that demand higher flow rates and lower energy consumption.

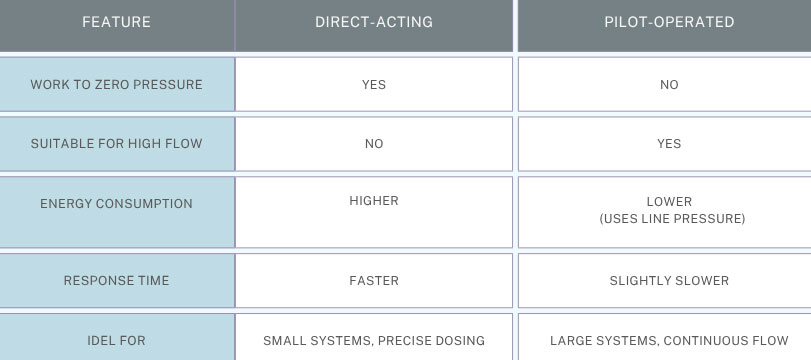

Side‑by‑Side Comparison Table

Here’s a quick reference table to help you compare both types at a glance:

By reviewing these points, engineers can easily match the valve type with their system requirements.

Factors to Consider When Choosing

When deciding between a direct acting solenoid valve and a pilot operated solenoid valve, consider these key factors:

- System pressure: If your system operates at zero or very low pressure, a direct acting model is essential. For pressurized lines, a pilot operated valve is often more efficient.

- Flow rate: Large-bore or high-flow applications demand pilot operated valves, while low‑flow systems benefit from direct acting designs.

- Media type: For gases, chemicals, or viscous fluids, direct acting valves often provide more reliability.

- Frequency of operation: Pilot operated valves are more energy-efficient for continuous operation.

- Power source: Direct acting valves typically consume more power, as the coil must generate enough force to lift the plunger.

Always review valve datasheets, flow curves, and application notes from trusted manufacturers like Aira Euro Automation, a leading industrial valve manufacturer in India, before finalizing your choice.

Also, read SS vs Brass Solenoid Valves: Which One Fits Your System Best?

Application Use Cases

The right valve type can make a big difference in system efficiency and longevity.

- Direct Acting Solenoid Valves: Perfect for medical dosing machines, laboratory instruments, small fuel gas systems, and precise chemical feeders.

- Pilot Operated Solenoid Valves: Ideal for steam line controls, large irrigation systems, municipal water treatment plants, and HVAC chillers in industrial setups.

By aligning your choice with the specific operational needs, you can reduce failures, improve efficiency, and extend the lifecycle of your equipment.

Match the Valve to the Job, Not Just the Spec Sheet:

In summary, use a direct acting solenoid valve for precise, low‑flow, low‑pressure systems and a pilot operated solenoid valve for high‑flow, high‑pressure applications. Choosing the right type ensures optimal performance, lower maintenance costs, and improved reliability.

Not sure which solenoid valve suits your system?

Get expert help from the technical team at Aira Euro Automation, India’s leading industrial valve manufacturer. We’re here to help you make the best choice for your application.

For any further assistance or customized solutions, feel free to reach out to Aira Euro Automation today!